Blog Search

Blog Search Results for ""

This week on the dyno THIS COMING WEEK...Monday doing a 99 XCR800, Stock vs

DynoPort pipes, Vforce reeds, shim kit to raise cylinders, modified heads to compensate and then some...

Wednesday we have a SkiDoo600 with a 734 big bore...

Friday we'll be tuning another D&D F8 top end with a Bikeman modded

stock pipe and maybe a new version of a D&D big bore single....

THIS IS BUGGING ME: some guy posted on the web, whining about not

wanting to pay $20 for DTR because he heard that all we say here is

aftermarket stuff doesn't work?! So he has a stock F7 with 132 HP that

I can put on our dyno and tune with timing and fuel only to close to

150 HP. A bone stock 700 pump gas twin with 150 HP!! Did Arctic

Cat/ Suzuki leave anything on the table? Does a factory stock 700 twin

capable of 150 HP have bad reeds? Is the stock F7 single pipe low

on HP? Did Arctic Cat goof on the best possible airbox intake? Give us

all a break. The 03 snowPro intake was huge like the high $ billet

aftermarket intake horns, but 04 and later airboxes have the smaller

high velocity intakes like the F7s-- could the smaller intake inlets

make more HP at peak revs due to airbox sound wave tuning? Or should

you poke a bunch of holes in your well-tuned airbox for "bullboys" and

let a bunch of HP robbing hot air into your intake??

Last Friday I had a guy from Maine tune his F7 dragracer w/ 500'

factory drag ECU. He came with a large diameter 03 snowpro intake,

switched to a stock F7 intake and he increased top end airflow CFM with

the smaller stock F7 air intake. With that stock airbox horn in place

he tuned to 151 HP.

So this whining guy with the 132 HP F7 can pay big bucks for big reeds,

big air horn, aftermarket pipe, big loud can and still may have

132 HP. Or he can read our stuff, figure out the facts, and have great

fun if he can find an instrumented dyno to tweak upon. The whining guy

has all the parts in his bone stock sled to make 150HP. All it takes is

tuning to get him there, or (wisely) partway there. My own tinking is

based upon the many sleds tuned here ONLY with fuel reduction and

timing increases, those 132 HP F7s are perfectly reliable for

intelligent people at 140-145 HP. And those 145 horse guys have stock

reeds, stock pipes, stock airboxes, and stock mufflers.

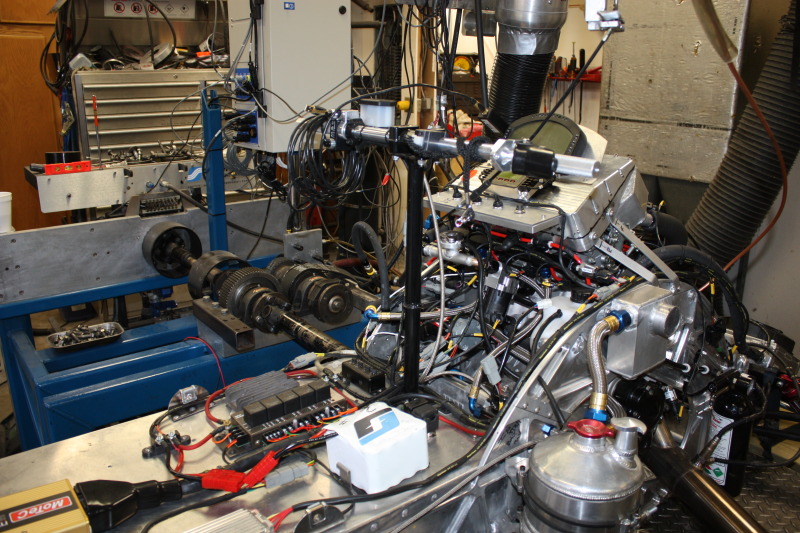

This week and Boss Noss tuning I had cancellations on Mon Tues this week, I had reserved midweek to update my SF901 Software to read 02 sensor A/F ratio. Computer savvy Sean Ray and Bender Racing's Terry Paine were a great help. This would enable us to read A/F ratio on complex return system EFI sleds like 900 Fusion (a multi-hour plumber's nightmare) by simply sucking exhaust gas through a wide band O2 sensor. Now it's easy to measure airflow CFM mechanically, then the new software should crunch the numbers and give us fuel flow lb/hr and BSFC without actually measuring fuel flow. Two strokes eat )2 sensors but the time savings justify that.

I had a nostalgia Wildcat650 mod on the dyno Tuesday, we struggled with that since it was a mod sled solid mounted (solid mounts on most twins are a nightmare causing fuel foaming and fuel flow shutoff even while float bowls are going dry)). Today (Friday) was my first Firecat of the week-- Tim Smith dialed in his Bikeman F8 with Bikeman mod single and Boondocker. He picked up 3 or 4 HP by removing his loud can and reinstalling his stock quiet muffler. I'll let him tell which brand of obnoxiously loud can he removed. Then we dialed him in 11.5/1 from EGV opening to 8100, plus we made sure his part throttle cruise was a safe 13/1 or close to that.. And since he has a peak airflow-robbing 440 snopro intake, he is going home to reinstall his stock intake but will have to bump up his high RPM Boondocker settings to compensate.

The dyno will be humming this weekend, two sleds Sat and two or more Sunday. Monday AM David Crampton F7, then Tues a mod F7 and F8. Then hoping on Wednesday to have Bill Looneytoon dial in his Lancaster NY asphalt drag champion DD F9, now with monster single and stock muffler, to make it trail safe. The Boondocker is great for that--Bill can have an 85 octane program plus two others in his Boondocker box-- maybe one for 92 and one for race gas. It takes only seconds to switch programs.

This weekend between sessions I will try to post our first Boss Noss tuning session. Hint: sometimes you are lucky enough to get what you pay for.

This week Today I had Kim Stout from PA, bone stock 05 F7 ( another lean one)

dyno tested with stock pipe/ muffler, Speedwerx pipe and can, Speedwerx

pipe and stock muffler, Bikeman mode F7 stock pipe and stock muffler.

Will post those eye-opening numbers after I get some non-cat stuff

posted.

Tomorrow, we're dyno tuning the Doo 827 (blogged earlier), then Wed I'm

Mr Mom (but I have time during school for any local tuneup from

10am-2pm), Thursday Jeff from Surelock performance dialing in his own

F8, Friday Bill Mead Boondockering a Bikeman F8 w/ D&D Y and

Monster single.

this dyno session ZR800 Boss Noss The sled on the dyno right now is an essentially stock ZR900 EFI with

speedwerx slightly high compression head and SLP twin pipe, bondocker

box, and Boss Noss nitrous oxide injection system. We tweaked for a few

hours today, fuel flow was way too high even with fuel valves nearly

shut, Boss Noss told sled owner they has forgotten to include some fuel

regulator, we will have that red label tomorrow AM. Watch DynoCams.

thursday AM Bikeman Erich will be here--dyno evaluating (they'tre

surely already dyno tuned on his own SuperFlow dyno) for SnowWeek, will

blast off for Old forge/ slickers to be there 5:00pm.

Things we will be testing I have in my possession a DynoPort Fusion Single pipe kit. I

would like to find other Fusion owners who have SLP pipes/ SLP

programming, HTG or other big bore, etc. Call me at 585-993-2777 to

discuss.

Mach Z stuff needs to be addressed, since all we've done here is

plugging compression release, DNE mild trail porting, etc... anyone

with twin pipes, big bore, etc etc please call me too.

The Boss Noss kit we had here has been sent off to a Firecat owner in

the Southern Tier of NY, he is installing it now, will bring back for

dyno tuning late this month or early next month. 200 HP or bust?

The rush is on Sorry Pol Yam Doo guys, the cats are pounding on my door again.

I have mortgage payments to make, and though I'd like to do more non-cat stuff, they are coming one after another.

This year the big deal is mod F7's with EFI and Boondocker boxes.

Today we tweeked Pete Nixon's lake race F7 ported by him, D&D

monster twins, and DTR programmed Boondocker. 2 1/2 hours dyno

time total $300 he's dialed in at 12.5/1 from valve opening

to where the pipes go dead, 165 HP. The Boondocker

numbers are a bit bizarre but the final result is flat dandy A/F

ratio that should be fine for his 2000' canadian radar runs.

Tuesday 11/22 two custom built F8s-- Jeff from Surelock Perf has one in the AM, Tom Reynolds has another in the PM.

Wed 11/23 my wife (court reporter who I met, in divorce court 20+

years ago) works, our 7 year old son is off from school so I have to be

Mr Mom.

Thursday Thanksgiving I will get shot if I dyno that day. I will sit on

the couch watching Macy's Thanksgiving Parade, pretending to enjoy that

knowing full well that a screaming sled on the dyno would be much more

fun.

Friday, a D&D F9 carbed, trying to dial in reliable HP with Bill LT

DiFranco hopefully helping out with tuning. Friday PM Robert Murray,

Bikeman F8 that has been troublesome in terms of HP output, back to BM,

now sled seems to run well, dyno evaluation late Friday.

Saturday Darrell Gaglianese brings his F7 carb to test with Bikeman spacers and with Supreme Tool mechanical EVs.

Monday-Wed SnowWeek editor Tim Erikson will be in NY

dealing with the DTR SW Adirondack Shootout, hoping that we will

have sleds to certify, I'm planning to train Tim on the SuperFlow dyno,

let him make a few "pulls".

The first official DynoTech “BlowUp”

I had a nostalgia Wildcat650 mod on the dyno Tuesday, we struggled with that since it was a mod sled solid mounted (solid mounts on most twins are a nightmare causing fuel foaming and fuel flow shutoff even while float bowls are going dry)). Today (Friday) was my first Firecat of the week-- Tim Smith dialed in his Bikeman F8 with Bikeman mod single and Boondocker. He picked up 3 or 4 HP by removing his loud can and reinstalling his stock quiet muffler. I'll let him tell which brand of obnoxiously loud can he removed. Then we dialed him in 11.5/1 from EGV opening to 8100, plus we made sure his part throttle cruise was a safe 13/1 or close to that.. And since he has a peak airflow-robbing 440 snopro intake, he is going home to reinstall his stock intake but will have to bump up his high RPM Boondocker settings to compensate.

The dyno will be humming this weekend, two sleds Sat and two or more Sunday. Monday AM David Crampton F7, then Tues a mod F7 and F8. Then hoping on Wednesday to have Bill Looneytoon dial in his Lancaster NY asphalt drag champion DD F9, now with monster single and stock muffler, to make it trail safe. The Boondocker is great for that--Bill can have an 85 octane program plus two others in his Boondocker box-- maybe one for 92 and one for race gas. It takes only seconds to switch programs.

This weekend between sessions I will try to post our first Boss Noss tuning session. Hint: sometimes you are lucky enough to get what you pay for.

This week Today I had Kim Stout from PA, bone stock 05 F7 ( another lean one)

dyno tested with stock pipe/ muffler, Speedwerx pipe and can, Speedwerx

pipe and stock muffler, Bikeman mode F7 stock pipe and stock muffler.

Will post those eye-opening numbers after I get some non-cat stuff

posted.

Tomorrow, we're dyno tuning the Doo 827 (blogged earlier), then Wed I'm

Mr Mom (but I have time during school for any local tuneup from

10am-2pm), Thursday Jeff from Surelock performance dialing in his own

F8, Friday Bill Mead Boondockering a Bikeman F8 w/ D&D Y and

Monster single.

this dyno session ZR800 Boss Noss The sled on the dyno right now is an essentially stock ZR900 EFI with

speedwerx slightly high compression head and SLP twin pipe, bondocker

box, and Boss Noss nitrous oxide injection system. We tweaked for a few

hours today, fuel flow was way too high even with fuel valves nearly

shut, Boss Noss told sled owner they has forgotten to include some fuel

regulator, we will have that red label tomorrow AM. Watch DynoCams.

thursday AM Bikeman Erich will be here--dyno evaluating (they'tre

surely already dyno tuned on his own SuperFlow dyno) for SnowWeek, will

blast off for Old forge/ slickers to be there 5:00pm.

Things we will be testing I have in my possession a DynoPort Fusion Single pipe kit. I

would like to find other Fusion owners who have SLP pipes/ SLP

programming, HTG or other big bore, etc. Call me at 585-993-2777 to

discuss.

Mach Z stuff needs to be addressed, since all we've done here is

plugging compression release, DNE mild trail porting, etc... anyone

with twin pipes, big bore, etc etc please call me too.

The Boss Noss kit we had here has been sent off to a Firecat owner in

the Southern Tier of NY, he is installing it now, will bring back for

dyno tuning late this month or early next month. 200 HP or bust?

The rush is on Sorry Pol Yam Doo guys, the cats are pounding on my door again.

I have mortgage payments to make, and though I'd like to do more non-cat stuff, they are coming one after another.

This year the big deal is mod F7's with EFI and Boondocker boxes.

Today we tweeked Pete Nixon's lake race F7 ported by him, D&D

monster twins, and DTR programmed Boondocker. 2 1/2 hours dyno

time total $300 he's dialed in at 12.5/1 from valve opening

to where the pipes go dead, 165 HP. The Boondocker

numbers are a bit bizarre but the final result is flat dandy A/F

ratio that should be fine for his 2000' canadian radar runs.

Tuesday 11/22 two custom built F8s-- Jeff from Surelock Perf has one in the AM, Tom Reynolds has another in the PM.

Wed 11/23 my wife (court reporter who I met, in divorce court 20+

years ago) works, our 7 year old son is off from school so I have to be

Mr Mom.

Thursday Thanksgiving I will get shot if I dyno that day. I will sit on

the couch watching Macy's Thanksgiving Parade, pretending to enjoy that

knowing full well that a screaming sled on the dyno would be much more

fun.

Friday, a D&D F9 carbed, trying to dial in reliable HP with Bill LT

DiFranco hopefully helping out with tuning. Friday PM Robert Murray,

Bikeman F8 that has been troublesome in terms of HP output, back to BM,

now sled seems to run well, dyno evaluation late Friday.

Saturday Darrell Gaglianese brings his F7 carb to test with Bikeman spacers and with Supreme Tool mechanical EVs.

Monday-Wed SnowWeek editor Tim Erikson will be in NY

dealing with the DTR SW Adirondack Shootout, hoping that we will

have sleds to certify, I'm planning to train Tim on the SuperFlow dyno,

let him make a few "pulls".

The first official DynoTech “BlowUp”

thursday AM Bikeman Erich will be here--dyno evaluating (they'tre surely already dyno tuned on his own SuperFlow dyno) for SnowWeek, will blast off for Old forge/ slickers to be there 5:00pm.

Things we will be testing I have in my possession a DynoPort Fusion Single pipe kit. I

would like to find other Fusion owners who have SLP pipes/ SLP

programming, HTG or other big bore, etc. Call me at 585-993-2777 to

discuss.

Mach Z stuff needs to be addressed, since all we've done here is

plugging compression release, DNE mild trail porting, etc... anyone

with twin pipes, big bore, etc etc please call me too.

The Boss Noss kit we had here has been sent off to a Firecat owner in

the Southern Tier of NY, he is installing it now, will bring back for

dyno tuning late this month or early next month. 200 HP or bust?

The rush is on Sorry Pol Yam Doo guys, the cats are pounding on my door again.

I have mortgage payments to make, and though I'd like to do more non-cat stuff, they are coming one after another.

This year the big deal is mod F7's with EFI and Boondocker boxes.

Today we tweeked Pete Nixon's lake race F7 ported by him, D&D

monster twins, and DTR programmed Boondocker. 2 1/2 hours dyno

time total $300 he's dialed in at 12.5/1 from valve opening

to where the pipes go dead, 165 HP. The Boondocker

numbers are a bit bizarre but the final result is flat dandy A/F

ratio that should be fine for his 2000' canadian radar runs.

Tuesday 11/22 two custom built F8s-- Jeff from Surelock Perf has one in the AM, Tom Reynolds has another in the PM.

Wed 11/23 my wife (court reporter who I met, in divorce court 20+

years ago) works, our 7 year old son is off from school so I have to be

Mr Mom.

Thursday Thanksgiving I will get shot if I dyno that day. I will sit on

the couch watching Macy's Thanksgiving Parade, pretending to enjoy that

knowing full well that a screaming sled on the dyno would be much more

fun.

Friday, a D&D F9 carbed, trying to dial in reliable HP with Bill LT

DiFranco hopefully helping out with tuning. Friday PM Robert Murray,

Bikeman F8 that has been troublesome in terms of HP output, back to BM,

now sled seems to run well, dyno evaluation late Friday.

Saturday Darrell Gaglianese brings his F7 carb to test with Bikeman spacers and with Supreme Tool mechanical EVs.

Monday-Wed SnowWeek editor Tim Erikson will be in NY

dealing with the DTR SW Adirondack Shootout, hoping that we will

have sleds to certify, I'm planning to train Tim on the SuperFlow dyno,

let him make a few "pulls".

The first official DynoTech “BlowUp”

I have mortgage payments to make, and though I'd like to do more non-cat stuff, they are coming one after another.

This year the big deal is mod F7's with EFI and Boondocker boxes. Today we tweeked Pete Nixon's lake race F7 ported by him, D&D monster twins, and DTR programmed Boondocker. 2 1/2 hours dyno time total $300 he's dialed in at 12.5/1 from valve opening to where the pipes go dead, 165 HP. The Boondocker numbers are a bit bizarre but the final result is flat dandy A/F ratio that should be fine for his 2000' canadian radar runs.

Tuesday 11/22 two custom built F8s-- Jeff from Surelock Perf has one in the AM, Tom Reynolds has another in the PM.

Wed 11/23 my wife (court reporter who I met, in divorce court 20+ years ago) works, our 7 year old son is off from school so I have to be Mr Mom.

Thursday Thanksgiving I will get shot if I dyno that day. I will sit on the couch watching Macy's Thanksgiving Parade, pretending to enjoy that knowing full well that a screaming sled on the dyno would be much more fun.

Friday, a D&D F9 carbed, trying to dial in reliable HP with Bill LT DiFranco hopefully helping out with tuning. Friday PM Robert Murray, Bikeman F8 that has been troublesome in terms of HP output, back to BM, now sled seems to run well, dyno evaluation late Friday.

Saturday Darrell Gaglianese brings his F7 carb to test with Bikeman spacers and with Supreme Tool mechanical EVs.

Monday-Wed SnowWeek editor Tim Erikson will be in NY dealing with the DTR SW Adirondack Shootout, hoping that we will have sleds to certify, I'm planning to train Tim on the SuperFlow dyno, let him make a few "pulls".

The first official DynoTech “BlowUp”

|

|

“Blow Up” is a commonly used euphemism among performance sledders to describe a seized piston—stuck in the bore because it temporarily grew bigger than the hole due to lean operation or deto. That euphemism annoys me because a stuck piston is not a “blowup”—it’s very non-destructive, non terrifying like a “blowup” would imply. I have always thought that the term “blow up” should be reserved for something more serious than a crankshaft that no longer turns, with something awry, but easily fixable inside the engine that is preventing normal rotation.

When funnycar racer John Force says he “blew up”, you know something way more violent than a stuck piston occurred.

In November I had my first real, true sled “BlowUp” on the dyno.

Terry and Mike Queenan had the Queenan Brothers Racing Hayabusa powered asphalt sled here to tune. This was to be a fun session—the fellow who provides parts and tuning for the Motec EFI system for Queenans (as well as the Al Anabi drag cars and bikes) was remotely monitoring the DTR tuning session from his home office in California, making fuel/ timing tweaks after each run via internet and observing the dynocams.

Creeping up on revs and boost (I think we were only running 11 psi boost and 410 HP) this fellow noted, watching data during each dyno test, that oil pressure had dropped a bit—perhaps due to rising oil temp? We cooled the crankcase for a few minutes before the next run. But what we did not realize was that a rod bearing on the big end of one of the engine’s aftermarket connecting rods was beginning to seize on the crank journal—perhaps smearing rod bearing material into the crank oil journals preventing total loss of oil pressure. This friction would eventually create heat that would in the next six seconds of boosted operation cause the rod to try to friction- weld itself to the crankshaft, then turn blue and eventually grab and snap sending parts flying.

On dyno test 10, we ran the engine up to 11,500 RPM and a sudden, loud snap accompanied a 7’ diameter ball of fire that enveloped the expensive area of the sled all the way to the ceiling tiles in the equally expensive dyno room!

This fire was accelerated by the 80mph air from the dyno air supply ducts—making it look exactly like one of John Force’s Funny Car “blowups” where headgaskets squeeze out and spew oil onto the headers creating one of those nasty, terrifying oil fires and an out of control funnycar. But in this case it was the rod cap blowing out the front of the Hayabusa crankcase, showering the cherry red header/ turbo with engine oil and creating the first DTR fireball.

I bolted from the control console, grabbing one of the 25 year old, but previously unused Halon fire extinguishers, and ran into the dyno room and with two pounds of Halon completely extinguished the fire. Terry and Mike Queenan were duly impressed with the speed at which Jr. Fire Marshal Jim was able to run from the control console, grab the the extinguisher and reach and address their burning sled. Halon is great stuff—today banned by the greenies but still said to be available, at a premium, from suppliers who have a stash of this stuff.

But with the fire extinguished, there was still a substantial amount of oil left on the dyno table beneath the sled….what if this sled was running down the dragstrip at 180mph instead of sitting on my diamond plate steel table?

That unburned oil, instead would surely have been spewed and drizzled in front of the smooth rubber track with instant loss of traction and directional control! It’s one thing to have an engine explode (truly “blow up”) and shut a sled down, but the prospect of dumping oil directly in front of the smooth rubber track is terrifying considering what we all know might happen should a high speed sled/ rider encounter a guardrail or concrete barrier at 180 mph plus!

Fortunately, Queenan’s sled features a high tech multi-stage dry sump oiling system which minimizes unnecessary oil volume within the crank case and the sled also has a solid pan beneath the motor which trapped some of the oil from spilling out under the chassis. Without these features, the fire on the dyno table and the potential real-world scenario could have been much, much worse.

Why not add some sort of diaper-like oil catcher like the top fuel racers use? For them, dropping oil mostly between the two rear tires is not a huge control issue, but NHRA is mostly concerned with downtime necessitated by cleaning up the mess. But sled racers with boosted four stroke engines approaching 10 HP per cubic inch will surely occasionally “blow up” engines, inevitably dropping oil directly in front of the tracks. It would be wise to deal with the inevitable spewing oil ahead of time.

From now on, people bringing heavily boosted engines to DTR must endure a pre-test fire drill.

SuperFlow Windyne software, SFD files Sorry about confusing new subscribers with these quick-for-me-to-upload SFD files.

Go to www.superflow.com, click on free windyne software download, then you're all set to view SFD files on DTR.

Open articles w/ SFD files, click on one SFD file, it opens

automatically as a graph that you can edit as desired. To view numeric

data, X out graph and the graph closes, and is automatically replaced

with OBSERVED NUMERIC DATA FROM THAT RUN. To see corrected data, click

on number 2 box above observed data, and you then see STANDARD

CORRECTED DATA (corrected to 60 degree F dry air, sea level 29.92 in hg

baro).

Then to save this test for later viewing or comparing with

other tests, click on FILE. Then click "save as" and save the SFD

file to your computer with the same numbering as I use. Also under FILE

you can click TEST DESCRIPTION to see what we did/ changed for this

test. Also you can click PREFERENCES and then click CHANNEL ORDER to

see any desired test information (ie: Baro pressure, air temp,

TimeS[seconds of dyno run time], fuel pressure, water temp,etc). BMEP

numbers are available, but won't be exactly be accurate unless exact

bore/stroke/displacement has been entered prior to test session. I

will try to remember to accurately enter that info into the database

prior to testing so BMEP numbers and Volumetric Efficiency % will be

perfect.

Now open another SFD test file, and if you leave graph open you can

click OVERLAY then click SAVED TESTS below to open and graphically

compare any other tests you've saved yourself.

Dyno tuners here can get their own dyno runs downloaded onto a

3.5" disc for their own comparison of DTR posted SFD files.

When I do other testing I will continue to attempt to make time to

include printed test data (from excell files) in the articles.

SuperFlow 902 dyno terminology explained Dyno Terminology—Fresh and Refresh

Dyno Terminology—Fresh and Refresh

The new SuperFlow 902 software has some subtle differences in channel headings in our test data compared to our original 25 year old SuperFlow 901 software. For long term DTR members I need to clarify the difference, and for new DTR members I need to explain the channel information in our dyno printouts, and what each channel means to us.

EngSpd RPM self-explanatory—this is RPM, and on engines with digital tachs, the readings have proven to be identical from dyno to sled. But analog sled tachometers are another story—vast differences can be seen from digital dyno RPM to analog sled tachometer readings. So it pays to have analog sled tachometers calibrated electronically (Aaen does this for a small fee) or with a digital tach like those sold by Stihl (less than $100) for tuning chainsaws. Those are perfectly accurate. But keep in mind that the peak HP RPM on our dyno tests is with pipe(s) extremely hot. And since the speed of sound increases with temperature, the HP peak in the field may be at lower RPM (trail riders on-off-on throttle) or at higher RPM (lake runners or mountain climbers who might spend minutes at WOT). Sled dragracers used to think that they achieved best acceleration by clutching to the “peak torque RPM” which often occurs 2-400 rpm lower than dyno test HP peak. But now we know that we clutch to a shifting HP peak—cool pipes on takeoff will make peak HP several hundred RPM lower than hot dyno test pipes, and finding that constantly changing peak HP RPM is critical in creating best acceleration.

STPPwr CHp horsepower, corrected to 60 degrees sea level baro 29.92 in hg.

This is derived by taking RPM x torque lb/ft divided by 5252. Complicated initially but it takes into consideration the twisting force and how quickly it can be done (RPM). HP is what we need to create acceleration and maintain top speed. Read on:

STPTrq Clb-ft this is the twisting force, or torque that the crankshaft is exerting at any given RPM, corrected to 60 degrees sea level barometer 29.92 in hg. But by itself, torque does no work—it takes speed—lots of speed—to do meaningful “work” (HP). To emphasize that, I sometimes talk about me (200 lb Jim) riding my Schwinn bicycle with 12” long pedal cranks. With my 300 lb girlfriend riding on my shoulders (facing forward of course), by grunting and lifting my butt off the bike seat I can make 500 lb/ft of torque at the pedal crank! That kind of torque should create wicked acceleration, shouldn’t it? But my spindly legs can only muster 3 RPM! So based upon the math RPM x torque lb/ft/ 5252 = HP that means that I can make about ¼ HP. Not bad for a 62 year old. But if I were instead twisting the throttle on a Honda 90cc scooter with 8 lb/ft at 5000 rpm I would be making 7.5HP—accelerating much harder—even with my 300 lb honey riding with me! No contest. It takes HP to create acceleration. We need a combo of torque and lots revs to do work—to make HP.

FuelAB- fuel flow into the engine in pounds per hour. This is a combination of the two dyno fuel flowmeters (flowmeter A and flowmeter B), measuring fuel flow from the sleds’ EFI pump to the rail, or from the mechanical pump to the carbs. Flowmeters can be used individually to measure N2O flow separately from carbs/ EFI. But combining the two flow readings is necessary for computing BSFC.

FulA_B- fuel flow from EFI pump to rail (A) minus fuel flow from bypass regulator back to the tank (B). Can’t use a – so we must use a _ instead. Polaris uses this type of system.

BSFCAB and BSFA_B- pounds of fuel per HP per hour. 25 years ago when I bought this dyno system there was no manual to explain the significance of this number. Early adventuresome guinea pigs (including all of the current eastern US aftermarket sled modifiers) and I proceeded to just tune engines blindly to max HP and beyond until engines seized. But after our 100th piston or so, we realized that there was a pattern to this destruction if we went too far beyond max HP. Fuel flow is meaningful information and we finally understood that our race engines would make best power at @.55 lb/hphr and pump gas engines needed @.70 lb/hphr to be reliable. Don’t go lower than that! But today, with modern race engine configuration two stroke race engines can make best power closer to .50 lb/hphr and new stock engines can be completely reliable at .60 lb/hphr and even lower! SkiDoo ETEC EFI systems allow way less short-circuiting, and a greater percentage of fuel flow contributes to HP, and not blowing out the exhaust thus reducing BSFC to bizarrely low numbers. New cooling system designs like those used by Arctic Cat employ modern “reverse” cooling systems like all modern automotive race engines, deliver the lowest temp coolant to the combustion chambers where it’s needed most allowing way more deto-free power! High volume “bathtub” coolant passages are passé, and smaller volume but higher velocity “shrinkwrapped” head coolant passages scour heat from combustion chambers way more efficiently! They use high velocity, turbulent coolant flow to maximize heat transfer from hot engine parts to cold heat exchangers. “Low and slow” is for smoking barbecue meat, and for smoking pistons!

Air_1s scfm- This is the airflow through the engine in Standard Cubic Ft per Minute. The dyno flowmeter is affixed to the airbox, or inserted in the insulated duct from the DTR refrigerated air system to the sleds’ air intake.

AFRAB and AFRA_B ratio- this is the mathematical ratio of air pounds per hour/ fuel based upon the weight of the air (converted from CFM based upon air density) to pounds of fuel per hour. 10/1 is rich (richer than 10/1 can result in misfire), and 17/1 is lean (leaner than 17/1 can result in misfire).

LamAF1- the SF902 uses an Innovate wide band A/F ratio meter to measure exhaust gas, and give us A/F ratio readings. The O2 sensor can be plumbed into the exhaust via a bung welded into the pipe, or with a dyno probe—with a long ¼ ID steel tube inserted colonoscopy-like into the stinger/ muffler. This reading can show leaner than the mechanical reading if oxygenated fuel is used.

LM1air- if there is no airbox and no possibility of accurate airflow readings, then approximate airflow SCFM can be determined by comparing mechanical fuel flow and the wideband A/F ratio. The math is done by the 902 computer and SCFM is shown.

ExhPrs psig- this is the average gauge pressure inside the tuned pipe(s) measured with a combination pressure transducer/ open element temperature probe in the fat part of a pipe center section. To generalize, 4.0 psi seems to be optimal in creating max HP in two stroke engines. If backpressure is lower, then power might be sacrificed. But then there is less possibility of detonation-producing active radicals being packed back into the combustion chamber by the pipe(s) return sound wave(s).

Exh_1 deg F- this measurement tells us that a pipe is at optimal temperature for best HP. Also it’s critical in telling us where peak HP occurs. The most savvy clutch tuners/ dataloggers can use this particular dyno test data to ensure that their engines run at max HP RPM from clutch engagement to the end of the track, or to the first turn.

Sunday's Dyno tuning results If you watched today's dynocams you saw us we struggle with Scranton PA sledder Mark Dombrowski's 04 Fusion fitted nicely by him with a Series 53 143N300 Aerocharger, intercooled and Boondocker boost measuring box. Mark was shooting for 200 pump gas HP. No problem.

For normally aspirated EFI mod sled it usually takes 2-2.5 hours to dial in Boondocker to perfection. The Boosted mode on this prototype Boondocker was new to me, but we dialed in A/F ratio safely at 5 psi boost in about three hours. But with perfect A/F ratio and 5 psi boost the HP and airflow CFM were only marginally higher than stock!

Turbo 2strokes normally show us 4-5 or more PSI pipe center section pressure higher than boost pressure, but this one measured 3 psi LESS than boost pressure!

After checking out the Aerocharger top to bottom, then even wiring the vane controller closed we failed to create backpressure or more than 5 psi boost.

Mark and his pal Allan (Allan brought a troublesome trail mod XCR800 to diagnose but he had a new-style clutch on an old-style crank end and we could not remove his clutch with either our new or old style pullers so no dyno tune was possible) are on there way home to Scranton.

Then I got a call from Sean Ray, on his way home from the Gaylord MI SnoX race where his Sean-tuned Tim Bender/Team Industries SnoX racers had some difficulties with a few perpexing mid-race seizures. Since I am the only person that has exceeded Sean's personal dyno piston seizures at DynoTech he occasionally consults with me when that happens on or off the dyno. When you tune for max HP you must dance around temp, baro, fuel octane, fuel reid vapor pressure, piston clearance, etc etc. I am confident the Sean-tuned racers will be fine for the next race.

Then I discussed Mark Dombrowski's very strange tuning session today with the Aerocharged Fusion 900. Sean has more boosted dyno tuning at DynoTech than me while we were doing Aerocharger kits next door. And Sean immediately suggested a split tuned pipe seam weld-- too common on boosted stock singles. Since that seam is hidden under the stock pipe's heat shield that is likely to be the culprit. I left a voicemail to Mark that he will get in a few hours. I'm hoping that when he pops off his heat shields tomorrow he will find the airflow/ boost/ HP robbing gap in the weld.

No dyno tomorrow I will be Mr Mom with my sick 7 year old son, Tuesday two lightly modded F7s, Wednesday Bill Looneytune DiFranco to dial in his F9 Lancaster Championship winning sled into a Canadian Trail-Safe monster with Monster single pipe and quiet stock can. Thursday I have another dyno session I can't remember what since my calendar is back at the dyno. Thurs PM Sean Ray is supposed to bring his dad's Fusion 600 sled (our first tuneup posted here) now poked out to 670cc and with aftermarket pipes. Sean and his family are scheduled to go to their camp in Tug Hill next weekend and it will suck to be Sean if his dad can't ride his new sled.

| First | Previous | Next | Last |

Archives

May 2015

March 2015

January 2015

December 2014

November 2014

November 2013

October 2013

September 2013

April 2013

March 2013

February 2013

January 2013

October 2012

September 2012

July 2012

May 2012

February 2012

December 2011

November 2011

September 2011

August 2011

June 2011

February 2011

January 2011

December 2010

November 2010

October 2010

September 2010

July 2010

June 2010

May 2010

April 2010

March 2010

January 2010

November 2009

October 2009

August 2009

June 2009

May 2009

April 2009

March 2009

February 2009

December 2008

November 2008

October 2008

September 2008

August 2008

July 2008

June 2008

May 2008

April 2008

March 2008

February 2008

January 2008

December 2007

November 2007

October 2007

September 2007

August 2007

July 2007

June 2007

May 2007

April 2007

March 2007

February 2007

January 2007

December 2006

October 2006

September 2006

August 2006

July 2006

June 2006

May 2006

April 2006

March 2006

February 2006

January 2006

December 2005

November 2005

October 2005

September 2005

August 2005

July 2005

June 2005

May 2005

April 2005

February 2005

January 2005

December 2004

November 2004

October 2004

September 2002

Misc.

Search

Admin Login